Best Insulation: San Antonio, Texas’s Leading Installation Contractors

Best Insulation

Branch Information

Branch Hours

| MON | 6AM – 5:30PM |

| TUE | 6AM – 5:30PM |

| WED | 6AM – 5:30PM |

| THU | 6AM – 5:30PM |

| FRI | 6AM – 5:30PM |

| SAT | Closed |

| SUN | Closed |

Leading Installation Contractor Services Near San Antonio

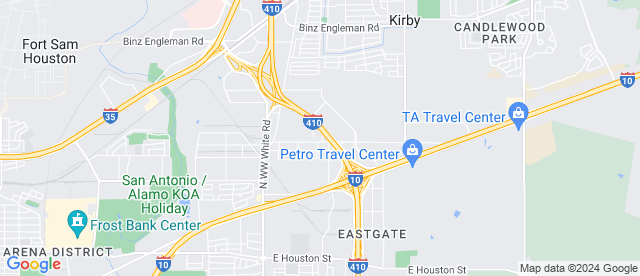

The San Antonio-based team of professional contractors at Best Insulation is ready to assist you with any renovation or building project with best-in-class installation services. Contact your local contractor at 4742 Cotton Belt Dr, San Antonio, TX for more details. As a TruTeam company, we have the resources to complete a variety of installation projects throughout the San Antonio area. We are ready to serve your needs, so contact Best Insulation now!

Who We Serve

Expert Installation Services for Homeowners in San Antonio

Trust Best Insulation for all your home installation needs in the San Antonio area. No matter the size of your home improvement project, the professionals at Best Insulation can help. Because we are a local TruTeam branch, we are backed by a national company with large suppliers and resources. This means Best Insulation can provide homeowners with a variety of product options and affordable installation costs. Give Best Insulation a call today for a free estimate on our installation services.

San Antonio Installation Services that Home Builders Trust

Count on Best Insulation to provide your home building project with skilled professional installation services and high quality building materials. Our trusted contractors are ready to help you with any size single family or multifamily home or renovation project. As a local branch of the TruTeam company, we are committed to improving our community, providing value, and meeting home builders’ needs throughout the San Antonio area. Call Best Insulation now to receive your free installation quote.

Trusted Installation Contractors for Commercial Builders in San Antonio

Best Insulation provides commercial builders in San Antonio with on-site project management, hassle-free quoting, and professional installation services to keep projects on schedule and on budget. Our installers live and work in the San Antonio area, and as a TruTeam company, we have the added advantage and resources of a national company and distribution system. Contact Best Insulation today to learn more about our commercial installation services and to receive a free estimate.

The Team You Can Trust

Get Free Quote

Nationwide

Network

Safety First

Culture

Thousands of

Expert

Installers

Installers

Millions

of Projects

Completed

Areas We Serve

Serving the greater San Antonio Area